The use of shaped pipes (having a square or rectangular cross section) is becoming increasingly popular because they have high strength and have good reliability indicators. At the same time, it is correct to bend a profile pipe without violating its integrity and functionality is not so simple. Particularly acute is the issue of bending profile pipes with their own hands at home.

Content

The main properties of profile pipes

The main difference between a profile pipe and a traditional one is its cross section. It is the difference in the cross section that does not always allow the use of the usual standard methods bending and achieving the required radius of curvature. In addition, the industry produces profile pipes from various materials: brass, copper, aluminum, etc., which entails the use of various bending techniques.

It should also be remembered that any mechanical influences in order to bend the profile pipes can introduce defects, and sometimes lead to the destruction of the structural integrity, so it will be useful to take care of the possibility of stretching the profile pipe when it is bent.

To achieve the required bending radius when doing the work yourself, you need to pay attention to the smoothness, leisurely movements, as well as the efforts that will greatly reduce the likelihood of damage and help to obtain the desired curved shape of the product.

The thickness of the walls of the profile pipe also affects the choice of the necessary bending method. But if you clearly imagine the end result, correctly and thoughtfully approach the choice of the method of bending a profile pipe, then the design obtained at the output will be distinguished by durability, aesthetics and reliability.

Helpful advice! Remember that the thermal effect on the profile pipe entails a change in the internal structure of the material from which it is made, and can significantly affect the properties of strength and reliability. Besides, repeated exposure to change the shape of the pipe (bending, bending), lead to its destruction.

Features of the use of a pipe bender

Let's move on to the options for how to bend a profile pipe at home. We note right away that it is quite difficult to bend a profile pipe with your own hands without the use of special tools, especially if the wall thickness of the pipe is large. The most acceptable and appropriate at home will be the use of a pipe bender. The pipe bender is characterized by the presence of a special drive wheel, which, when moving along one of the faces, allows the profile pipe to be bent as necessary for the user.

Pipe benders are manual and electric. In the first case, the bending of the profile pipe is carried out manually by setting the wheels of the pipe bender in motion with a special handle.This is acceptable if the cross section of the pipe is small, and the structure itself is not bulky and you can change its shape with your own hands.

Otherwise, when the scope of work and the dimensions of the pipe are large enough, an electric pipe bender is required, driven by a simple press of a button. The principle of operation is similar: the movement of the wheel along the edge. But the result is more aesthetic and less labor intensive.

If the work is disposable, then there is no point in buying special equipment and carrying out work at home, it is better to contact specialized companies, you can rent a machine. How to bend profile pipes without pipe benders will be given later.

Alternative pipe bending options at home

Let's consider how to bend a profile pipe without using special machines. It should be noted that the bending of the profile pipe along the radius must satisfy the following requirements:

- the desired wall thickness of the pipe should be more than 2 cm, otherwise bending is fraught with destruction of the integrity of the pipe structure;

- we put the pipe profile height Z> 2 cm, then the profile pipe bent over a length of 3.5 x Z will not be destroyed and will not lose reliability.

Important is the temperature of the product during bending. It is no secret that in the heated state it is easier to change the curvature of a metal product. But, if the work is done at home, it is imperative to follow safety precautions and monitor your actions.

Helpful advice! It should be noted that profile pipes with a profile height of up to 1 cm, do not need heating to give them a curved shape, whereas pipes withWith a profile height of more than 4 cm, do not bend it unambiguously with your own hands and without heating.

Bending profile pipes with a grinder

Another way to achieve the desired bend radius with your own hands is to use a grinder. In the place of the proposed bend, it is necessary to make several transverse cuts (usually they need three), then just bend the profile pipe with your own hands and weld the place of cuts with a welding machine.

Since the profile pipe has a section of the correct shape, the final product will have a completely aesthetic appearance (if you carefully grind the welded sections) with undisturbed strength indicators.

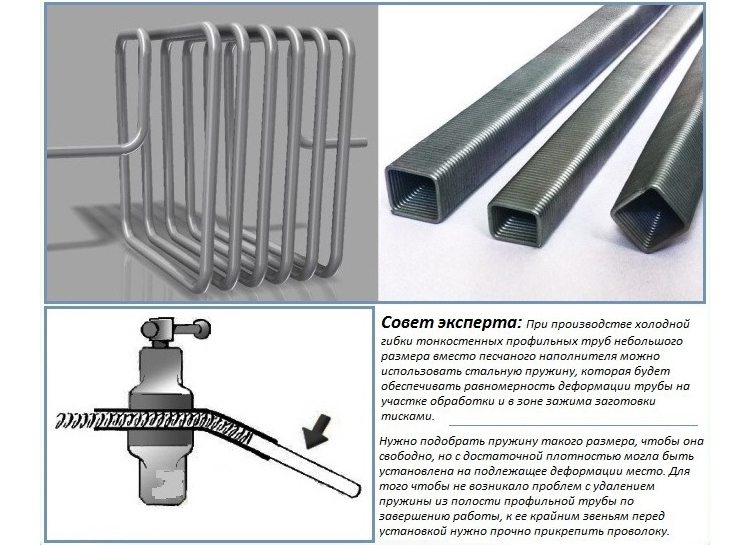

Spring Method

The method is quite simple and can be implemented as follows: you need to take a wire (preferably steel) with a thickness of about 2 mm, make a square spring out of it, which is inserted into the pipe, then it’s worth heating the place where it will bend and bending the pipe to the radius which is necessary. It is worth immediately monitoring how to bend the profile pipe correctly, since a heated pipe will not retain its ductility for long.

Helpful advice! When making a spring, make sure that its segments were one and a half to two millimeters less than the corresponding side of the section profile pipe. Under such conditions, it is not difficult to place the spring inside profile pipe.

Sand pipe bending

When it is not possible to carry out work in specialized workshops and the business is limited to home conditions and do it yourself, a wide variety of ideas come to the rescue on how to bend a profile pipe without spending a lot of financial and physical effort. Let us consider in more detail how to bend a profile pipe: at home, you can use sand that is necessarily sifted and dried. As well as wooden wedges, which are commensurate with the cut of the pipe and can be hammered into it.

The procedure is as follows:

- drive a wedge on one side of the pipe;

- pour sand inside;

- hammer a wedge on the other hand, thereby making a kind of stub.

Further, having fixed one end, it is possible to bend to the desired radius. Moreover, the bend can also be heated to facilitate the operation. The integrity and strength of the pipe will be ensured by the sand that is poured, which, after successful bending, can be removed by first breaking out wooden wedges.

How to bend a profile pipe with water

It is possible to bend profile pipes at home, as necessary according to the project, using water. In this case, the pipe should be made of copper or any other non-ferrous metal. It is necessary to close one of the ends of the profile pipe with a plug and pour water inside. It is important to ensure its presence at a negative temperature so that the water can freeze. In this state, bending with your own hands the profile pipes of both rectangular and square sections does not seem to be a difficult task.

Helpful advice! Remember, a profile pipe with a square cross section will bend easier closer to the ends, and not to the middle.