When laying or repairing engineering communications, the homeowner may be faced with the need to organize the rotation of the pipes. Of course, this can be done using fittings. But many people prefer to bend the polypropylene pipe without the use of additional connecting elements. After all, they are potential leak points that require constant monitoring and optional costs for their repair or replacement.

Content

A little theory of how to bend a polypropylene pipe

Bending is a process whose ultimate goal is to change the slope of the geometric axis of the pipe. It is accompanied by the appearance of elastic and elastoplastic deformations in the walls of this product. Compressive stresses arise on the inside of the bend, and tensile stresses arise on the outside.

The bending process causes a change in the shape of the profile. So, the initial annular cross section is transformed into an oval. The greatest ovality is observed in the center of the perish and decreases towards its beginning and end. This phenomenon is explained by the fact that the greatest compressive and tensile stresses account for the central part of the bent pipe. The formula by which you can determine the ovality of the profile in percent looks like this:

Q = {(Dmax - Dmin) / Dnom} * 100.

The parameters present in the formula correspond to the maximum, minimum, and nominal outer diameter at the bend point.

In order for the bent element to fit perfectly into the pipeline, the workpiece must be of a certain length. To calculate it, you can use the following formula:

L = 0.0175 * R * ὼ + l,

where: l is the length of the straight section of the pipe necessary for its capture, ὼ is the pipe bending angle in degrees, R is the pipe bending radius in millimeters.

Bending methods

Polypropylene is considered to be sufficiently solid, incapable of bending material. Moreover, most manufacturers do not recommend carrying out this procedure on pipes made on its basis, since they can lose their attractive performance. Therefore, the question may naturally arise, is it possible to bend pipes made of polypropylene? The answer is clear: you can. But only with the right approach.

You should know that the value of the maximum permissible minimum bending radius of polypropylene pipes depends on their outer diameter. You will find these data for the most popular sizes in the table below.

Table 1

| Diameter, millimeters | Bending radius, millimeters |

| 50 | 400 |

| 40 | 320 |

| 32 | 256 |

| 25 | 200 |

| 20 | 160 |

Today, there are several ways to bend such products.

How to bend a polypropylene pipe with a building hair dryer

To do this, you will need:

- a template having the desired angle. It is necessary to make it from solid material;

- building hair dryer.

First you need to make a template.It will be required to fix the pipe in a given position.

Important! Particular attention should be paid to the formation of a flat surface of the template. This will prevent dents, chips or kinks. In addition, the surface of the bent pipe will remain flat.

Then, with a pencil or marker, mark the area of the future bend on the pipe. At the same time, it is recommended that its length matches the length of the template.

Having done this, install the building hair dryer so that nothing interferes with bringing the propylene pipe segment to it. For uniform heating of the deformable area, gently and accurately move the pipe section along the flow of hot air.

The heating of the pipe should be carried out while monitoring its condition. It is necessary to place the pipe in the template and fix it when it acquires the ability to bend easily (this will happen at a temperature of about 140 ° C), but has not yet managed to lose its shape as a result of melting (temperature is about 170 ° C). So that the result is not deplorable, you must fall into this interval. On the template, the pipe cools down and retains the formed angle. After that, you can proceed to install it.

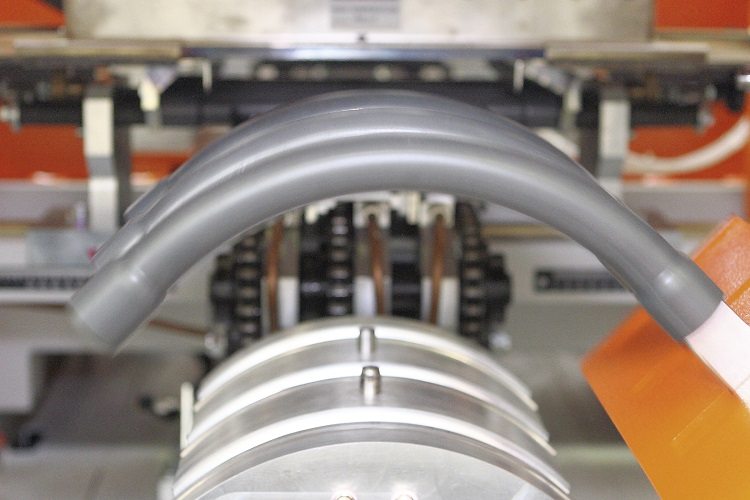

How to bend a polypropylene pipe using a molding machine

This work is carried out in three stages.

- Manufacture of wood-fiber board (Fibreboard) frames. It is useful for giving the polypropylene pipe the desired shape.

- Creating a silicone shell. At this stage, a molding machine is needed. The sheath made with its help provides at the moment of fixing the pipe in the frame the protection of its surface from potential damage: scratches, dents and chips.

- Bending procedure. Insert the polypropylene pipe into the shell, fix the product in the frame of the fiberboard, place the structure in the molding machine. Under the influence of high temperature, the polypropylene softens, starts to sit on the frame and takes the necessary shape. Take out the product after 10 minutes. After removing the pipe from the frame, leave it to cool completely.

When creating a frame from a fiberboard, remember that its geometric dimensions must correspond to the length and diameter of the pipe. After the dimensions are adjusted, carefully treat it with sandpaper - smoothness is needed so that there are no signs of the use of the frame on the finished pipe.

Bending of polypropylene pipes on high-tech equipment

By such are meant liquid (glycol, glycerin) baths, electric furnaces, as well as gas or steam chambers. They serve to pre-heat pipes. Electric furnaces are inferior in performance to vertical liquid glycerin baths.

To perform local bends on long pipes, an air tunnel electric furnace is used. The places where the pipe passes through its end caps must necessarily have a seal along the outer diameter, and the ends of the pipes with plugs are plugged.

Important! When heating is carried out in a vertical liquid bath, the workpiece must be immersed so that its end protrudes above the surface of the liquid by at least two outer diameters.

If the dimensions of the heating equipment do not allow heating the bending pipe along the entire length at once, it is necessary to bend in several steps. But this process will be more laborious and complicated, since without skills it is easy to spoil the product.

The temperature of the liquid should be 165 + 5 ° C. If the heating procedure is carried out in an electric furnace, the air temperature must be maintained at 20-30 ° C higher compared to the value of this parameter of the liquid in the bath.Temperature adjustment is carried out using thermostats, and if there are none, manually according to the thermometer. It is necessary to carry out heating uniformly along the length of the bent section and along the wall thickness. The workpiece, heated to a predetermined temperature, without loss of shape stability, must be in a highly elastic state.

Important! Reheating of an already bent segment is not allowed.

Many homework masters have heard about the so-called pipe benders. Therefore, they ask the question of how to bend a polypropylene pipe using such units. One of the most common technologies is to roll a heated pipe around a template without using filler. It is used if it is necessary to create a bending radius greater than 3.5 times the outer diameter of the workpiece, provided that the ratio of the thickness of its wall to the outer diameter is more than 0.065. Actually, this parameter determines the nomenclature of polypropylene pipes, which can be bent without filler.

The main requirements put forward by this technology are formulated as follows:

- the gap between the bale roller and the bending template should be less than 10 percent of the outer diameter of the pipe being bent;

- the diameter of the bale roller and the streams of the bending template should be equal to the nominal diameter of the workpiece.

Angle control is carried out on the dial located on the template. To obtain the required value of this parameter, it is necessary to bend the polypropylene pipe taking into account its spring - 10%.

After completing the bending process, the resulting product must be subjected to external inspection. The surface of the bent part should be smooth and even. Minor marks from the bending tool are allowed. But dents and cracks should be absent.

Important! The quality of the work performed is determined by the ovality of the profile at the bend. The requirement of regulatory documents in this regard will be met if the value of this parameter does not exceed eight percent.

Cold bending polypropylene pipe

This method can also be used. But it must be borne in mind that here the probability of spoiling the pipe increases significantly.

All of the above methods of bending polypropylene pipes have proven their viability in practice. But, again, their implementation requires a thorough approach. Only then can the final product be operated for a long time.