Polycarbonate pipes have appeared relatively recently, but have already taken advanced positions in the building materials market. They are distinguished by unique technical characteristics, due to which they have penetrated into many areas of modern life. Polycarbonate products are incredibly reliable and at the same time have an attractive appearance, so they are often used as an interior decoration.

Polycarbonate pipes - lightweight, durable and easy to process material suitable for translating design ideas

Content

About Material

Polycarbonate refers to polymers of synthetic origin and is a linear polyester. This polymer is colorless and has high heat resistance - up to 200 ° C. He is also able to tolerate sharp temperature jumps. Resistance to mechanical influences allows the use of products from this material in the construction of railings and various partitions.

Important! Transparent polycarbonate pipes are also used for conducting light. In addition, such a material is characterized by a low coefficient of water absorption, and also it does not tend to expand upon thermal exposure.

The dielectric and optical properties of this material, as well as its anti-corrosion properties, make polycarbonate products attractive to customers.

The advantages of polycarbonate pipes

Pipes from this polymeric material have various qualitative characteristics and have many advantages:

- many processing options (including welding);

- when cutting or drilling products do not crack;

- resistant to precipitation;

- possess excellent anticorrosive qualities. Do not collapse when interacting with aggressive chemical compounds (acid, alkali);

- light weight, which simplifies their transportation and installation;

- differ in high fire resistance;

- the working temperature range for such pipes is from –60 to +120, and in some cases up to 200 ° C.

- inert to various building materials;

- have a high transparency coefficient;

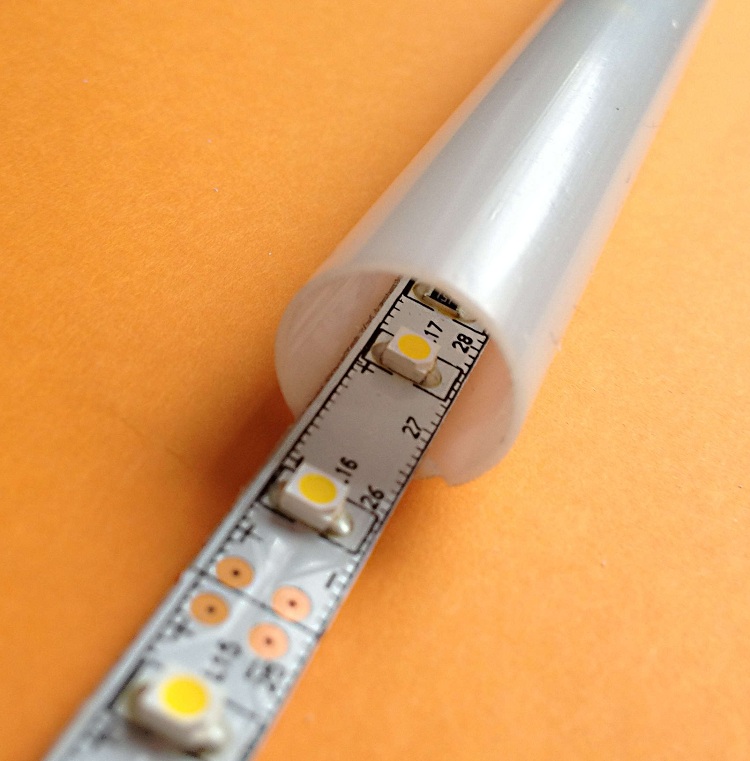

- can perform an insulating role for wiring;

- environmentally friendly, therefore their use does not entail harm to humans;

- withstand high internal pressure;

- have a low coefficient of water absorption;

- the range of colors for such products is incredibly wide;

- resistant to mechanical damage.

Due to all of the above characteristics, polycarbonate products have gained recognition in the market of building materials and are used for the installation of various structures.

The difference between polycarbonate pipes from others

The transparency of polycarbonate pipes is almost the same as that of glass analogues (only 2% less). In addition, they are 2–2.5 times lighter than glass, and strength indicators make it possible to produce polymer parts with a minimum wall thickness. The connection of individual polycarbonate elements in a single design is carried out in several ways:

- gluing;

- welding;

- coupling connection.

Processing polycarbonate tubes is much simpler than glass parts.Conventional wood or metal tools can be used to cut or drill these polymer products.

If you compare polycarbonate parts with acrylic, the former have better mechanical properties. This allows the use of polycarbonate pipes with a smaller wall thickness for the same purpose. The impact resistance of such parts is 10 times higher than that of acrylic pipes. In addition, polycarbonate pipes can replace not only glass or acrylic, but also others (for example: fiberglass, aluminum).

Scope of polycarbonate pipes

As mentioned above, the scope of use of such products is incredibly wide. Due to their technical characteristics, they are used in many, sometimes non-standard, conditions. Consider the areas in which the use of polycarbonate pipes is most in demand.

Lighting and design. They are widely used for lighting and all kinds of lighting. Illuminated pipes are popular as a decor element and can be performed in various configurations. Of these, fixtures and other lighting devices are often made that are suitable for such lamps: fluorescent, metal halide, etc. Also, these tubes are often used for mounting lighting in trains, subways, hospitals and other public places. This is due to the fact that polycarbonate parts are highly durable, and in the most crowded public places there is always a risk of damage to lighting fixtures by vandals.

Architectural lighting. Polycarbonate parts are ideal for lighting various architectural objects. They are durable, tolerate temperature extremes, and they are not afraid of the effects of snow and rain. Color-dynamic underwater lights are another device that includes a polycarbonate pipe. Such lamps are used to illuminate the water in the fountains.

Interior and advertising. The strength characteristics of these polymer products allow their use as various building envelopes. The possibility of lighting inside such a pipe allows you to make spectacular and bewitching decor elements from them. In the advertising field, they are used to design points of sale, at exhibitions, etc.

Polycarbonate tubes are inexpensive, and everyone can purchase them. Consider several non-standard options for using polycarbonate tubes at home:

- original flower vase;

- small fountain;

- dense tubes can be used for the installation of exhaust communications.

Among other things, from polycarbonate pipes create a lot of small, auxiliary products - souvenirs, shockproof packaging, etc.

Dimensions and other specifications

Primary colors of polycarbonate tubes:

- transparent;

- red;

- blue;

- yellow;

- green;

- bronze.

The standard wall thickness for such tubes is 1.5 mm. Section sizes vary from 25 to 50 mm. Less common are products with a diameter of 54 mm. As a rule, tubes are produced in segments from 1 to 6 m long.

Helpful information! Many manufactures produce customized products on order, as the use cases for polycarbonate pipes are practically unlimited.

There is a certain dependence of the transferred pressure on the diameter of the polycarbonate pipe. The larger the tube cross section, the less pressure its internal wall can withstand. This relationship is described in the table below.

Table 1

| Mm | The internal pressure that the pipe can carry, kg / cm² |

| 25 | 80 |

| 38 | 40 |

| 50 | 32 |

Colored polycarbonate

The color spectrum of polycarbonate products allows you to expand the scope of their use.But, as a rule, decoration of shopping centers and other public spaces is considered the most popular option for using colored tubes. Lighting tubes of red and dark blue colors are considered the most spectacular.

Often a polycarbonate tube is used to illuminate the halls of luxury restaurants. An installation of such details is able to interest people and become the "highlight" of a particular institution. It is not difficult to stick a colored film on an initially transparent pipe and equip the part with a lighting device.